What is the TWEI?

The Texas Water and Energy Institute provides a multi-disciplinary and multi-institutional approach to complex issues dealing with produced water, wastewater, and drinking water.Water Lecture Series

The Water Lecture Series allows the community, industry leaders, academia, and government agencies to come together to network and discuss state-of-the-art treatment technologies, challenges and opportunities.

Watch and LearnTWEI Products & Services

- Produced Water Analysis and Material Characterization

- Database / Produced Water Analytics

- Produced Water Technology Evaluation and Treatability Studies

Outreach

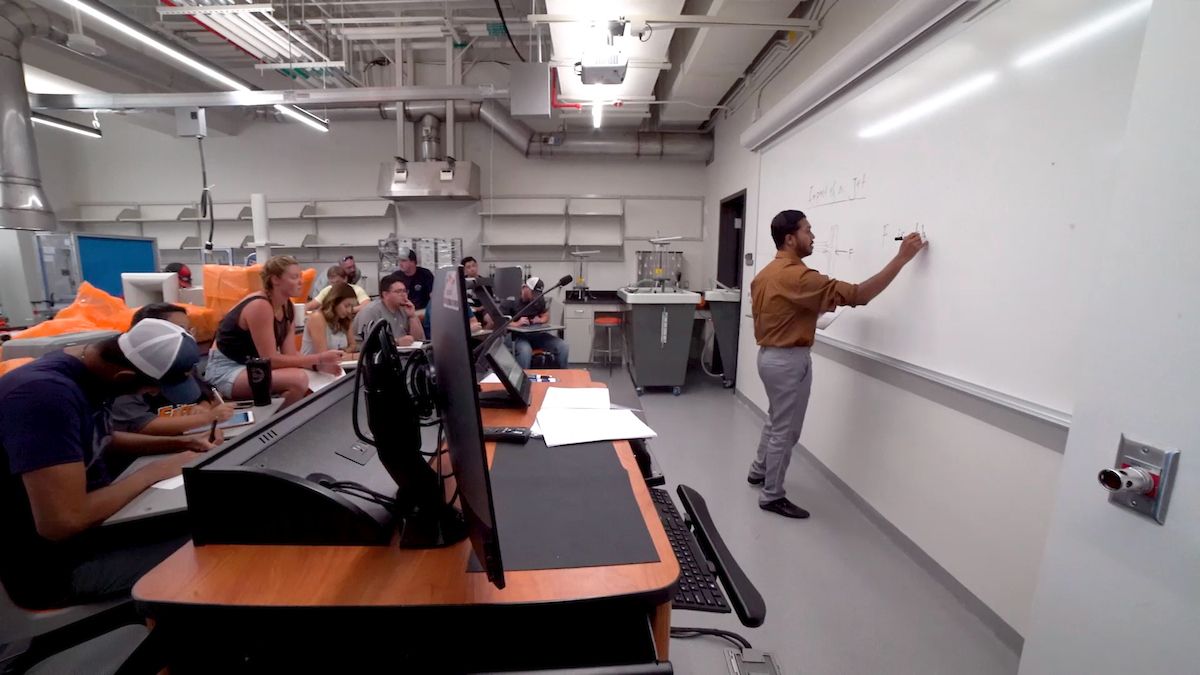

One of the strategic educational initiatives of the Texas Water Energy Institute at UT Permian Basin is to engage the community, industry, and academia. TWEI has several events and opportunities in place to achieve this goal. Whether the audience is K-12 , University students, advanced researchers or industry partners, TWEI is ready to engage and advance knowledge.