This machine was placed on the second floor of the engineering building and will serve as a learning tool for petroleum engineering students.

The University of Texas Permian Basin College of Engineering has been gifted a Hughes drill bit by a local Permian Basin family.

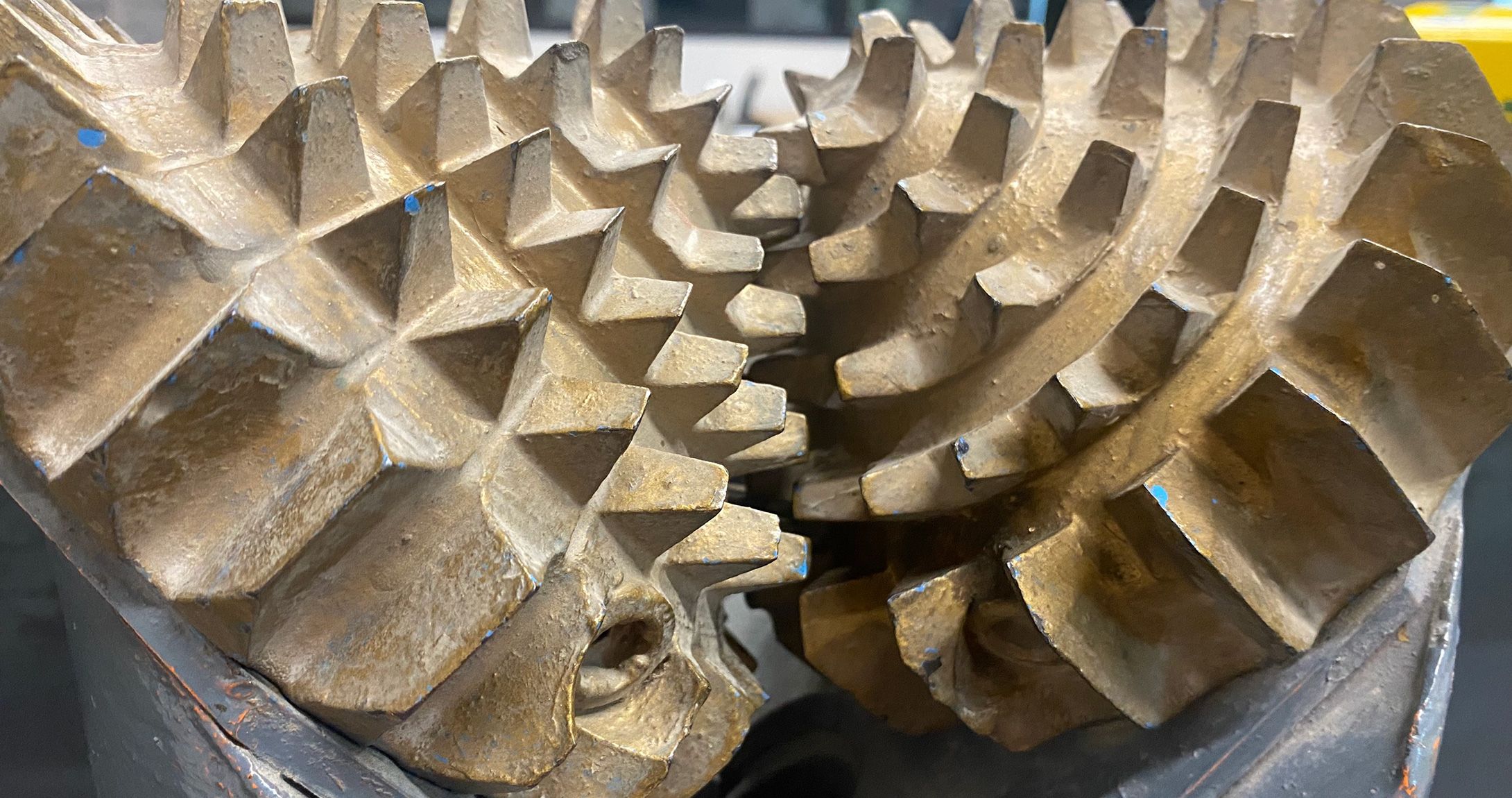

This original twin-cone rotary rock drill bit has been used to drill oil wells. It costs $3,500, weighs 78 pounds, and is still in working condition.

This original twin-cone rotary rock drill bit has been used to drill oil wells. It costs $3,500, weighs 78 pounds, and is still in working condition.

Prior to 1909, the oil industry used the traditional fishtail bit to scrape the rock and drill oil wells, however, these bits quickly dulled in service. The Hughes two-cone bit came into the picture as a solution to this problem. In 1906, Howard Hughes began experimenting with the idea of a bit consisting of two toothy, rotating steel cones that would pulverize the rock.

The revolutionary rolling action bit, which can rotate up to a hundred times a minute, crushes hard-rock formations with twin cone-shaped, hardened steel bits. These twin pieces are each equipped with 166 cutting edges, revolving on bronze bearings shaped to provide a large surface with reduced friction. The Hughes bit is a fantastic success story that can inspire students.

The Department of Petroleum Engineering’s Department Coordinator, Ahmed Kamel, said he believes the drill bit will benefit the program.

“The drill bit will be a great addition to the College of Engineering, and it will help educate undergraduate students on the evolution of drilling,” said Kamel. “With access to cutting-edge equipment, students develop practical skills that encourage them to excel academically and professionally.”

undergraduate students on the evolution of drilling,” said Kamel. “With access to cutting-edge equipment, students develop practical skills that encourage them to excel academically and professionally.”

This machine was placed on the second floor of the engineering building and will serve as a learning tool for petroleum engineering students.

“The faculty and students at UTPB recognize the importance of donors’ generosity and express their gratitude,” Kamel said. “The impact of this family's generosity will touch the lives of countless students, reminding us all that giving back to educational institutions can transform the lives of others and shape the Permian Basin for the better.”

This original twin-cone rotary rock drill bit has been used to drill oil wells. It costs $3,500, weighs 78 pounds, and is still in working condition.

This original twin-cone rotary rock drill bit has been used to drill oil wells. It costs $3,500, weighs 78 pounds, and is still in working condition. Prior to 1909, the oil industry used the traditional fishtail bit to scrape the rock and drill oil wells, however, these bits quickly dulled in service. The Hughes two-cone bit came into the picture as a solution to this problem. In 1906, Howard Hughes began experimenting with the idea of a bit consisting of two toothy, rotating steel cones that would pulverize the rock.

The revolutionary rolling action bit, which can rotate up to a hundred times a minute, crushes hard-rock formations with twin cone-shaped, hardened steel bits. These twin pieces are each equipped with 166 cutting edges, revolving on bronze bearings shaped to provide a large surface with reduced friction. The Hughes bit is a fantastic success story that can inspire students.

The Department of Petroleum Engineering’s Department Coordinator, Ahmed Kamel, said he believes the drill bit will benefit the program.

“The drill bit will be a great addition to the College of Engineering, and it will help educate

undergraduate students on the evolution of drilling,” said Kamel. “With access to cutting-edge equipment, students develop practical skills that encourage them to excel academically and professionally.”

undergraduate students on the evolution of drilling,” said Kamel. “With access to cutting-edge equipment, students develop practical skills that encourage them to excel academically and professionally.” This machine was placed on the second floor of the engineering building and will serve as a learning tool for petroleum engineering students.

“The faculty and students at UTPB recognize the importance of donors’ generosity and express their gratitude,” Kamel said. “The impact of this family's generosity will touch the lives of countless students, reminding us all that giving back to educational institutions can transform the lives of others and shape the Permian Basin for the better.”