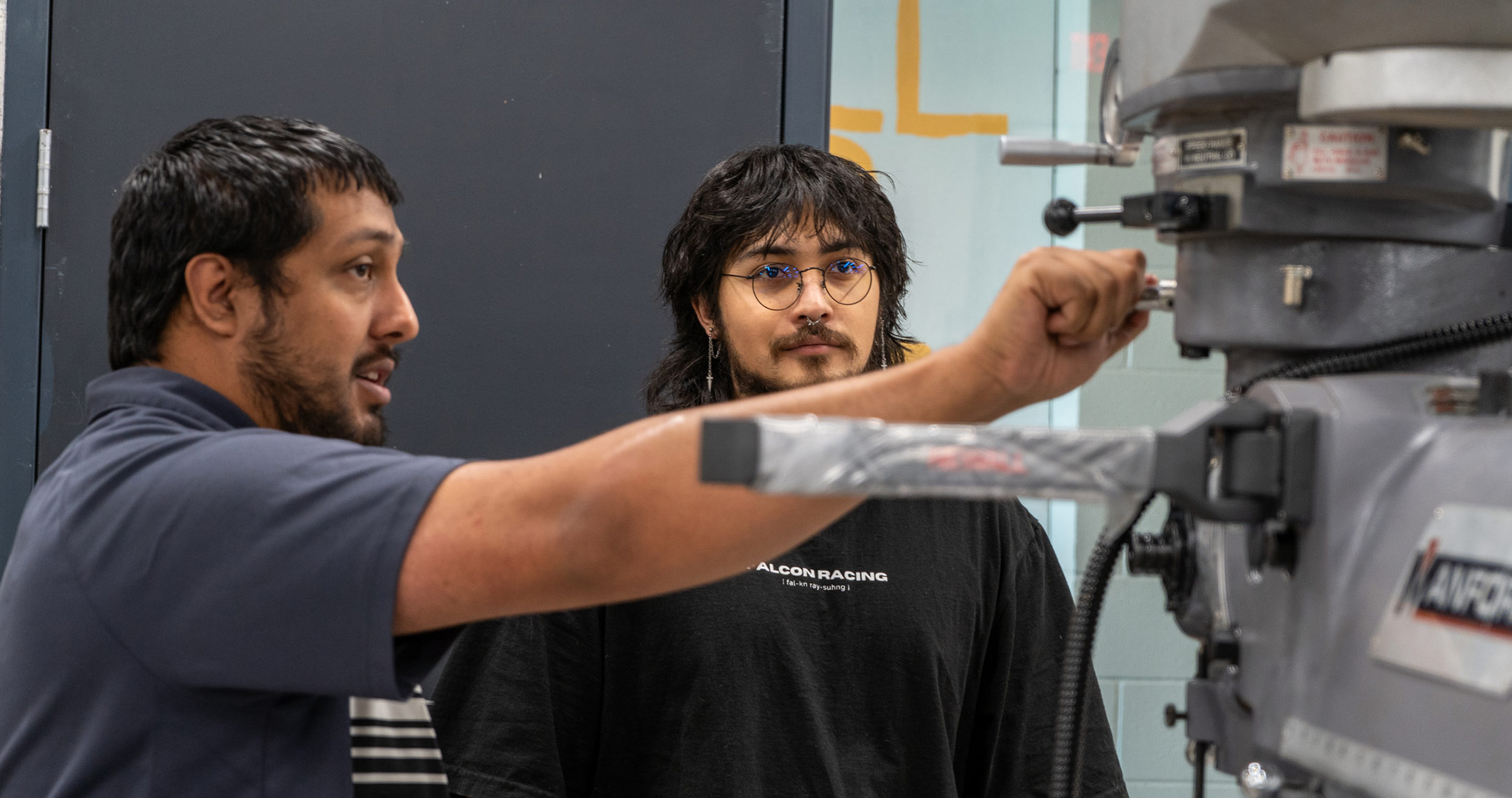

The University of Texas Permian Basin’s Advanced Manufacturing Center (AMC) is empowering students with hands-on experience using state-of-the-art manufacturing equipment.

Students in the Introduction to Manufacturing course gain practical skills on a wide range of advanced machinery, including FDM 3D Printers, Resin 3D Printers, Composite 3D Printers, CNC Plasma tables, CNC water Jet Tables, CNC Laser Cut Tables, Manual Lathes, Manual Mills, and more.

Students in the Introduction to Manufacturing course gain practical skills on a wide range of advanced machinery, including FDM 3D Printers, Resin 3D Printers, Composite 3D Printers, CNC Plasma tables, CNC water Jet Tables, CNC Laser Cut Tables, Manual Lathes, Manual Mills, and more.

They also receive training on Instron testing equipment and casting techniques, equipping them with a comprehensive foundation in modern manufacturing processes.

“The Introduction to Manufacturing course is equipping students with essential skills and knowledge about modern production processes, preparing them for possible careers in a rapidly evolving local industry. It is the first step that helps build a skilled local workforce to meet current regional needs and support continued development of new industries such as the local budding space industry,” said AMC Manager Jesse Chavez.

While students currently earn certificates of completion, plans are underway to expand the program to offer manufacturing degrees and certifications.

While students currently earn certificates of completion, plans are underway to expand the program to offer manufacturing degrees and certifications.

“Currently, every student that has actively shown up and participated has been offered an internship for the upcoming school year from multiple local manufacturing companies. In the long run, it is the launching point for careers and has even inspired a few students to dream of starting their own manufacturing companies,” said Chavez.

Many students have also used the University’s equipment outside of class hours to start their own side businesses designing custom metal signs and trinkets for local companies.

Emilio Ibarra, a student in the course, is studying to receive his master’s in mechanical engineering. He says the program has given him the opportunity to learn how to make things himself. He’s even working on building an ironman helmet, after the one he ordered on Amazon didn’t fit.

“In my recent classes we only saw videos of machines of what they did, how they design it. Here we actually get the hands-on experience of working with the machines,” said Ibarra.

“In my recent classes we only saw videos of machines of what they did, how they design it. Here we actually get the hands-on experience of working with the machines,” said Ibarra.

Senior mechanical engineering student Nathaniel Kleinbach says the course will give him a head start in understanding the equipment he’ll use after graduation.

“It’s been really exciting and enjoyable. It’s nice to be able to use the knowledge that we’ve learned in our classes to better understand how the equipment is used in the real word,” said Kleinbach.

He hopes to see the program continue to expand for future students as he has found it to be highly beneficial.

The lab is open to the community. Learn more about the Advanced Manufacturing Center.